What Is Lead Time?

Lead time refers to the duration between the start of a process and its completion. Specifically, it represents the time required to manufacture a product or provide a service for use by the customer. Lead time is commonly used in the manufacturing industry, supply chain management, and project planning.

Calculating Lead Time

The general formula for calculating lead time is straightforward:

Let’s break down the concept further with two examples:

Example 1 – Customer Order Fulfillment

Suppose a customer places an order for a customized product. The lead time for this scenario includes the following steps:

- Order Placement: The customer submits the order.

- Processing Time: The manufacturer processes the order, which involves tasks like design, production planning, and material procurement.

- Manufacturing: The actual production of the product takes place.

- Delivery: The finished product is shipped to the customer.

The lead time in this case encompasses all these steps, from order placement to product delivery.

Example 2 – Retailer Inventory Replenishment

For a retailer, lead time involves replenishing inventory. Here’s how it breaks down:

- Order Placement: The retailer places an order with the supplier.

- Supplier Processing Time: The supplier processes the order, prepares the goods, and ships them.

- Transportation Time: The time it takes for the goods to travel from the supplier to the retailer’s location.

- Receiving and Stocking: The retailer receives the goods and stocks them in their inventory.

The lead time for inventory replenishment includes all these stages.

Importance of Lead Time

Lead time serves several critical purposes:

- Work Scheduling: Knowing lead time helps organizations schedule work efficiently. It allows them to allocate resources and plan production or service delivery.

- Client Expectations: Providing clients with accurate lead time estimates ensures they know when to expect their desired products or services.

- Process Optimization: Analyzing lead time helps identify bottlenecks and areas for improvement. Manufacturers can make informed decisions to reduce lead time where necessary.

Types of Lead Time

As we delve into the intricacies of lead time, let’s explore its various types. Lead time manifests in four distinct sectors:

- Customer Lead Time:

- This refers to the duration between a customer placing an order and receiving the product. Several factors influence customer lead time, including the manufacturing process, shipping methods, and any other potential sources of delay.

- Material Lead Time:

- Material lead time represents the amount of time required from purchasing a material to transforming it into a finished product. Factors affecting material lead time include supplier processing time, transportation hours, and delays in material receipt.

- Production Lead Time:

- Production lead time encompasses the duration of creating a product after all necessary materials have been gathered. It can be influenced by manufacturing techniques, the availability of workers, and machinery downtime.

- Cumulative Lead Time:

- The cumulative lead time refers to the total time a product spends in production. This includes both active production time and the time spent assembling materials or utilizing manpower.

Cycle Time vs. Lead Time: Understanding the Difference

1. Cycle Time:

- Definition: Cycle time refers to the duration required for a product or process to complete a full cycle, starting from the beginning and ending at the same point.

- Measurement: It is typically measured within the production process itself.

- Focus: Cycle time emphasizes the efficiency of the production process and how quickly a single unit of work can be completed.

- Example: In manufacturing, cycle time would be the time it takes to produce one widget from raw materials to finished product.

2. Lead Time:

- Definition: Lead time represents the total time elapsed from the moment an order is placed until the product or service is delivered to the customer.

- Measurement: It spans the entire process, including order processing, production, transportation, and delivery.

- Focus: Lead time is customer-centric and considers the entire journey, from order placement to final delivery.

- Example: For an online retailer, lead time includes the time taken to process the order, pick and pack the items, ship them, and deliver them to the customer’s doorstep.

Key Takeaway:

- Cycle time focuses on the internal efficiency of a process, while lead time considers the end-to-end customer experience.

- Both metrics are essential for effective operations and meeting customer expectations.

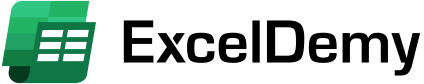

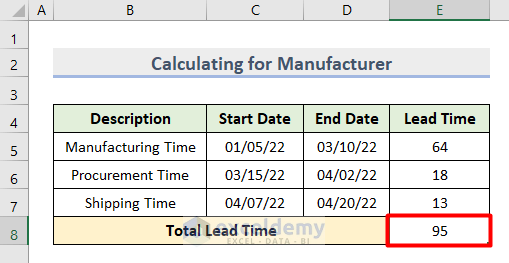

Example 1 – Lead Time Calculation for Manufacturer in Excel

- Component Descriptions:

- Insert the Descriptions of the components needed for manufacturing. Place these descriptions in cells B5 to B7.

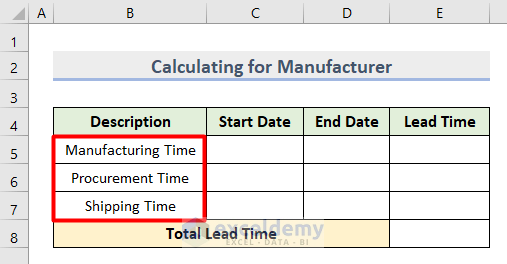

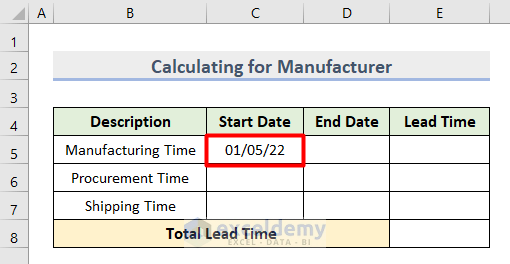

- Start Date:

- Enter the Start Date of the manufacturing process in cell C5.

- Note that the date might initially be in text format. We’ll convert it to a proper date format for calculations.

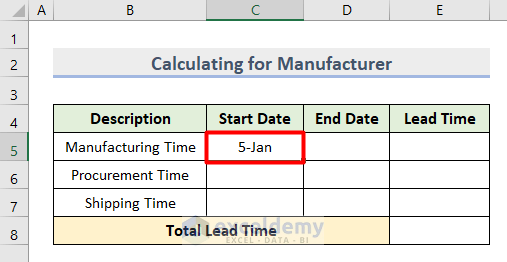

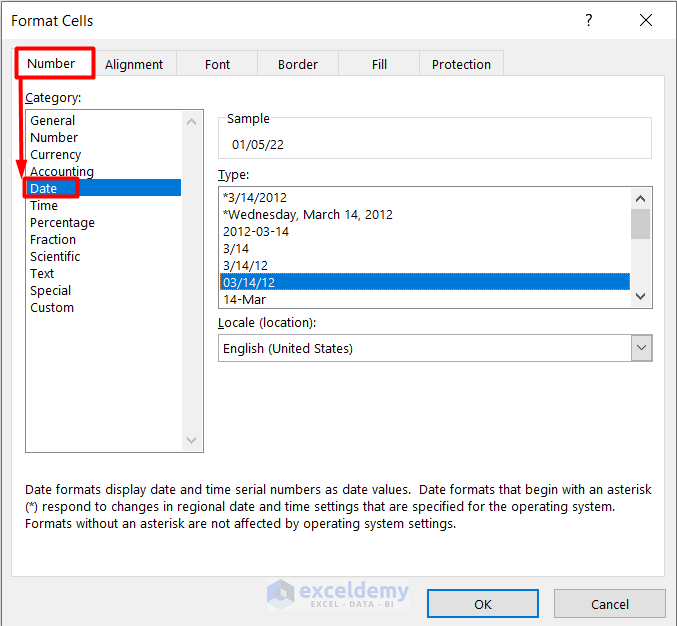

- Format Cells:

- Right-click on the start date cell (C5) and select Format Cells from the Context Menu.

-

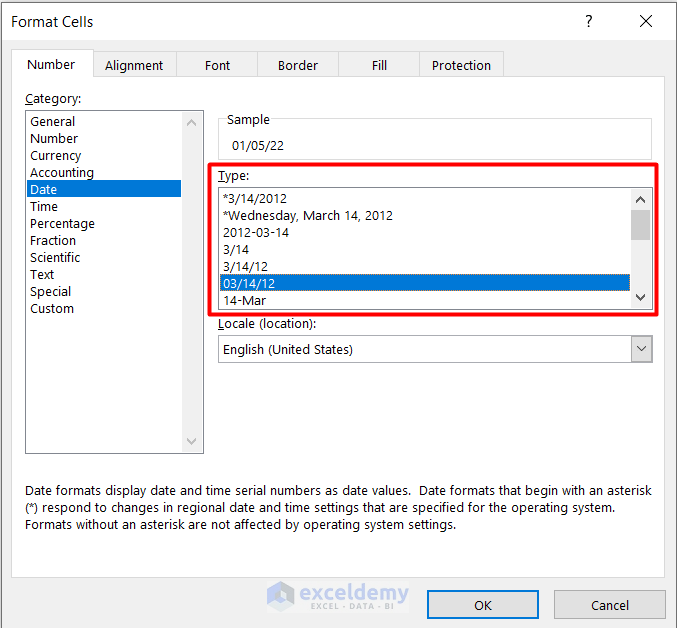

- In the Format Cells dialog, choose the Date category under the Number tab.

-

- Adjust the format as needed (e.g., choose the desired date format).

-

- Click OK to apply the changes. Now the start date is correctly formatted.

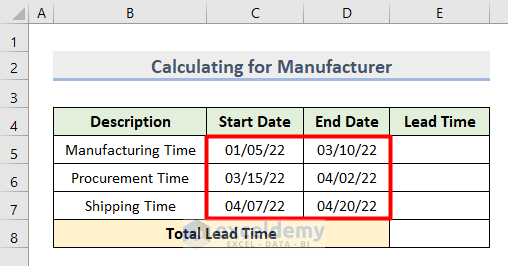

- End Dates:

- Similarly, insert the End Dates for each component in the cell range C5:D7.

- Calculate Lead Time:

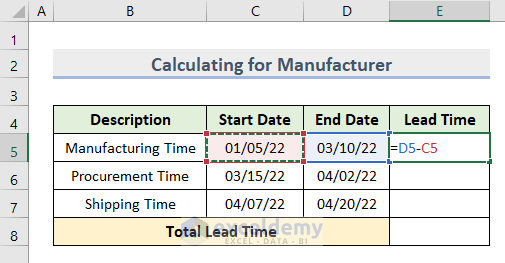

- In cell E5, enter the following formula to calculate the Lead Time for the first component:

=D5-C5

-

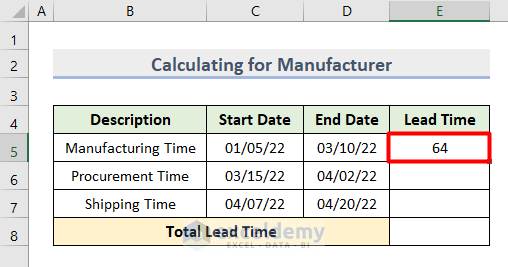

- Press Enter to see the lead time for that component.

-

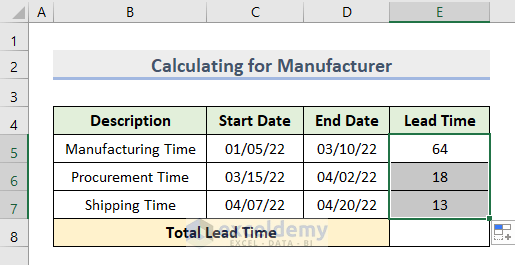

- Use the AutoFill tool to copy this formula down to calculate lead times for the remaining components.

- Ensure that the lead time values are formatted as Numbers.

- Total Lead Time:

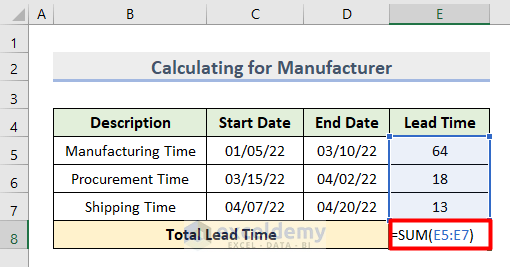

- In cell E8, use the SUM function to calculate the total lead time across all components:

=SUM(E5:E7)

-

- Press Enter to get the total lead time required by the manufacturer.

Read More: How to Calculate Lag Time in Excel

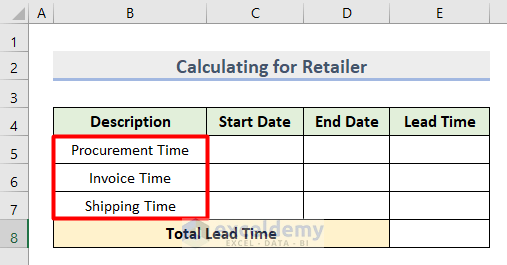

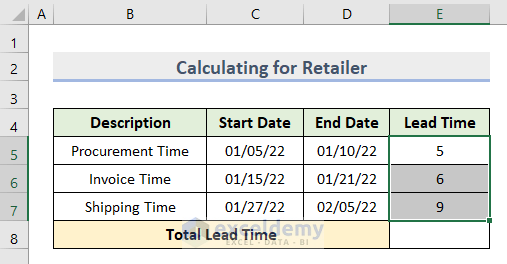

Example 2 – Lead Time Calculation for Retailer in Excel

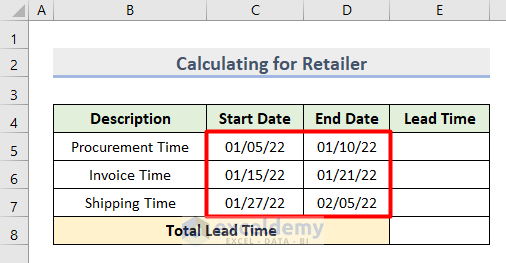

- Description and Dates:

- In cell range B5:B7, enter the Descriptions of the components.

- In cell range C5:D7, input the Start and End Dates for each component.

- Ensure that the dates are formatted correctly.

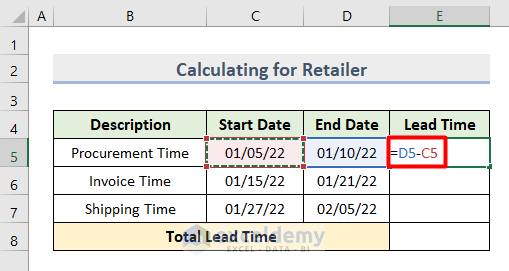

- Calculate Lead Time for Each Component:

- Enter this formula in cell E5 to get the Lead Time for the first component:

=D5-C5

-

- Press Enter and then use the AutoFill feature to apply this formula to the remaining components.

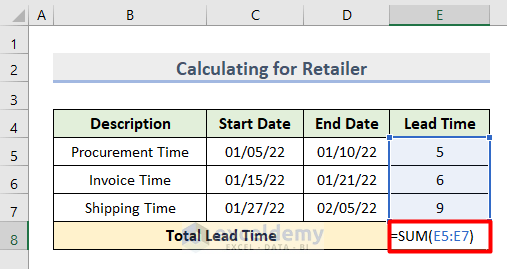

-

- Now, insert this formula in cell E8.

=SUM(E5:E7)

-

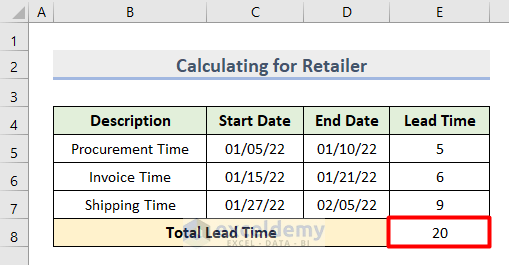

- Press Enter and you will get the Total Lead Time for a Retailer.

You can see that the amount of Lead Time is variable based on the type, process, and components. Therefore, we found that the Lead Time for manufacturing is larger than that of purchasing it as a retailer.

Download Practice Workbook

You can download the practice workbook from here:

Related Articles

- How to Calculate Total Hours in Excel

- How to Calculate Total Time in Excel

- How to Calculate the Duration of Time in Excel

- How to Calculate Median Follow-up Time in Excel

- How to Calculate Percentage of Time in Excel

- How to Sum Time in Excel

- [Fixed!] SUM Not Working with Time Values in Excel

<< Go Back to Calculate Time | Date-Time in Excel | Learn Excel

Get FREE Advanced Excel Exercises with Solutions!